|

Over the next several months' many growers will be harvesting and filling grain bins. A grain bin is a confined space and is also a Permit-Required Confined Space (PRCS), however, on most farms it is not thought of that way. Today I’d like to shed some light on confined space permits to have people more comfortable about the important role it plays in keeping people safe. I will take you through a couple areas of a confined space entry permit. See link; Sample Confined Space Permit |

|

A “Confined Space Entry Permit” Is a Checklist!

All pilots go through a preflight checklist…every time. Despite the repetitiveness of detail….it works. Skipping the checklist means you put your life and the lives of others at risk. The same is true for grain bin entry. Assuming the space is safe because you entered many times without incident is risky. All entrapments can be avoided with a checklist/confined space entry permit. (don’t let the word permit scare you off)

What is a Confined Space? (must meet all three)

- Large enough and arranged so the employee can fully enter the space and work

- Has limited or restricted entry or exit (grain bins, tanks, vessels, silos, hoppers, pits, excavations)

- Not primarily designed for human occupancy

What is a Permit-Required Confined Space? A confined space plus additional hazards….

- Hazardous Atmosphere

- Engulfment

- Entrapment and/or

- Other Serious Hazard

|

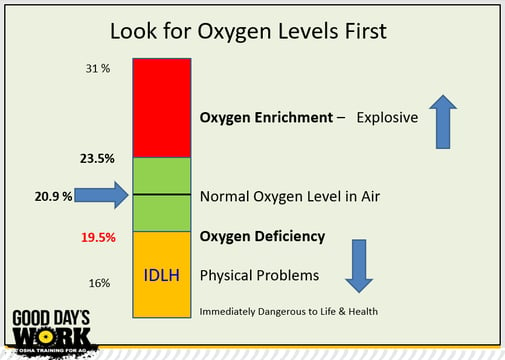

Atmosphere Why is it important? Most confined space deaths are caused by atmospheric hazards. Can’t see it, can’t smell it, people don’t know it’s there. Every farm must have a gas monitor(s) that meets all the needs of the operation….no exceptions! |

|

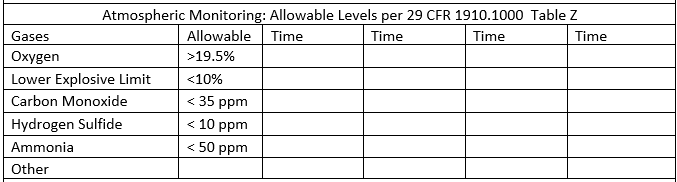

Atmospheric Monitoring - example of a confined space permit showing allowable levels

Typical multi-meters measure oxygen, lower explosive level (LEL), carbon monoxide, and hydrogen sulfide (oxygen content, combustibility/flammability, and toxic atmospheres). Evaluation of the whole space is a requirement as the space can very. Measure your oxygen first. Other gasses will displace the oxygen. If oxygen goes to 19.5% or below there is a problem, continue to investigate. Oxygen becomes hazardous if at 19.5% or below.

Why would an oxygen percentage go down?

To name a few….displacement by other gasses, consumption, reaction, lack of air movement, and more. Knowing the atmosphere is good, allows you to continue. Once you have the monitor, testing the atmosphere does not take long. Keep in mind toxic atmospheres can be caused by grain stored in a confined space; gasses are released during grain drying and the decomposition of grain.

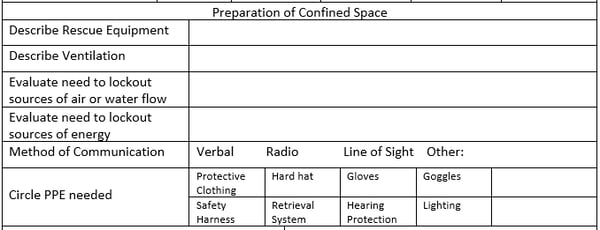

Preparation of Confined Space

Before entering a grain bin, describe rescue equipment that will be used when entering a grain bin. This is a key part of the checklist. It helps you think through what is needed. This part is not complex, however, designed to reduce errors and ensure consistency in carrying out a procedure safely.

|

A key component is the Lockout/Tagout (LOTO) Many facilities from old to brand new are simply not marked well enough to convey what each breaker controls and people are not informed/trained to know where to shut off the power. Does everyone know where the breakers are and what they power? Take action to identify power sources even if you must hire an electrician to help identify everything. All mechanical, electrical, hydraulic, and pneumatic which presents a danger to employees inside grain storage shall be de-energized, disconnected, locked-out and tagged, blocked, or otherwise prevented from operating. |

|

Do you have a LOTO system with locks and tags? Order them and set up the procedure to use them. Perform a dry run through with employees so they are comfortable with LOTO procedures.

|

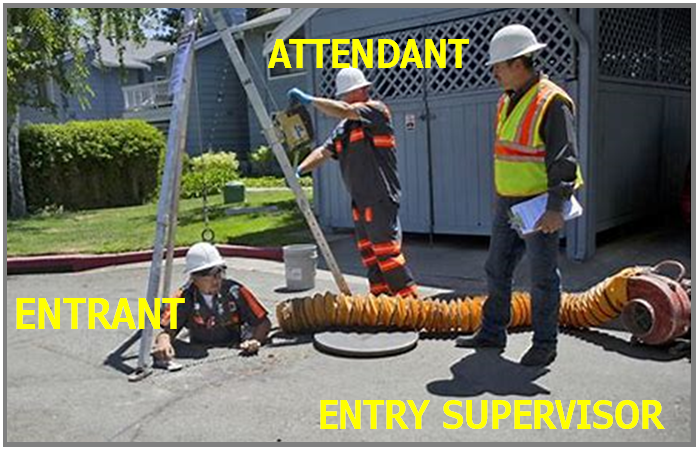

Never Work Alone! Another key component of confined space permit is permit roles. Here are some key definitions: Entry Supervisor – Has the overall accountability and responsibility for safe entry operations. This person authorizes, supervises, and terminates the entry. Entrant – this is an employee who has been trained, qualified, and authorized to enter the confined space. In short, this person knows the hazards during entry, knows how to use confined space entry equipment (PPE, harness, meter, radio, etc.). This person communicates with the attendant as necessary, to enable the attendant to monitor the entrants' status. |

Permit Entry Roles

|

Attendant – Knows the hazard of the space. Maintains voice and/or visual contact with the entrant and alerts entrant if there is a need to evacuate. They summons rescue and other services as soon as the attendant determines that the entrant may need assistance to escape. Shall not enter the space for rescue. They also warn unauthorized persons to stay away and to exit the area.

Now you have three people, three minds monitoring the overall activity with caution.

Wrap Up

This is not a comprehensive instruction guide. This note is to address the importance of using a confined space permit to think through the activity of entering a grain bin...before entry occurs. Once you acquire the necessary equipment and walk through the steps of filling out a confined space permit, you’ll find it doesn’t take an enormous amount of time.

Having a "zero-entry" mentality is always the best policy for grain bin entry. However we understand there are times when someone must enter one. Have a checklist (PRCS), be prepared with the proper equipment, and having people trained and in proper positions will save lives. I suggest the Confined Space, LOTO, and Electrical Safety courses from Good Day's Work.

A pilot goes through a checklist every time, no exceptions. This is no different. No matter how many farm employees you have, we recommend all growers follow permit-required confined space guidelines when entering grain bins. Once you work through the permit a couple times and rid yourself of the awkwardness of doing something for the first time, you'll find it easy to perform. For those that use a confined space permit consistently, please share your experiences with others!

Thank You for looking out for the safety of YOUR TEAM!

Good Day's Work Team