Fire Prevention Week, observed from October 5-11, 2025, is a reminder for every industry to refocus on safety. This year's theme, “Charge into Fire Safety: Lithium-Ion Batteries in Your Home,” highlights a modern risk that is increasingly relevant on farms and ranches. While the theme focuses on homes, these powerful batteries are now common in agricultural tools and equipment, bringing new fire hazards to our barns, shops, and fields.

Charge into Fire Safety This Fall: A Guide for Agribusinesses

Topics: Fire Safety, Fire Prevention Week, Fire Extinguisher, Battery Safety

Topics: grain bins, lockout-tagout (LOTO), Grain Bin Entry, grain bin safety, Checking Grain Bins

Farming is one of the most rewarding professions, but it also comes with unique risks. From unpredictable weather to equipment malfunctions, the potential for an emergency is always present. Having a clear, well-documented Emergency Action Plan (EAP) is not just a good idea—it's a critical tool for protecting your people, your animals, and your livelihood. An effective plan can turn a potential catastrophe into a managed incident.

Topics: emergency action plan, Fire Safety

Topics: tractors, machine guarding (PTOs/augers), ROPS, Tractor Safety, Tips, Tractor Safety Tips

At Good Day’s Work, we know that harvest marks the payoff for months of effort—a season of long hours, dedication, and big goals. But above all, we believe that nothing matters more than safety. Every year, we train and support agricultural teams so they can work efficiently and return home safe. The fast pace and powerful equipment on today’s farms create risks, but most accidents are preventable with the right habits and planning.

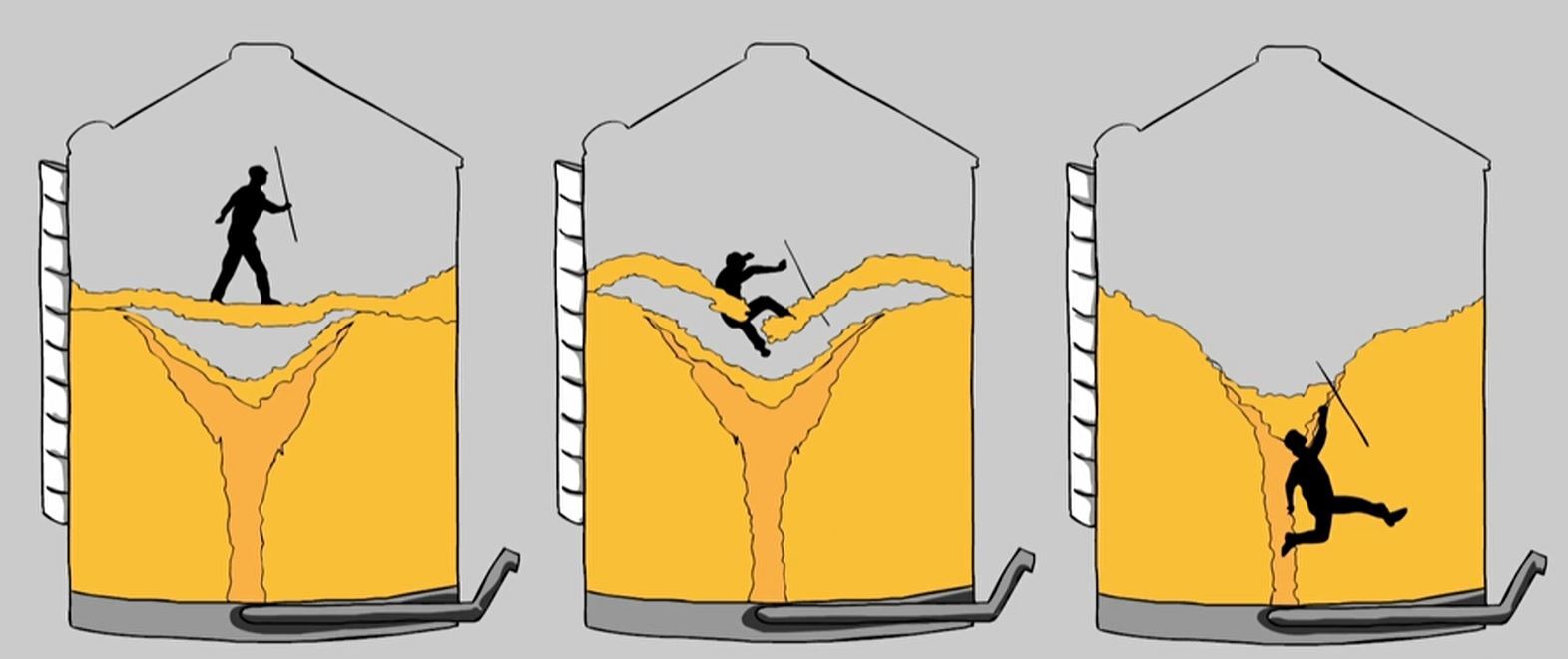

Topics: Checking Grain Bins, Harvest Safety, Fall Harvest

Topics: Fire Preparedness Checklist , Fire Safety

When it comes to agriculture, rewarding work often comes with risks. Agriculture is one of the most hazardous industries, and the dangers farmers and agricultural workers face daily are often unseen by the public. According to the U.S. Bureau of Labor Statistics, the fatality rate in agriculture is seven times higher than the average across all private industries. However, many of these risks can be mitigated with proper safety measures, training, and awareness.

Topics: safety culture, heat stress, slips/trips/falls, hazardous waste, rollover (ROPS), ROPS, Grain Bin Entry, Safety Hazards, Common Dangers in Agriculture, Grain Handling, Ladder Safety

At Good Day’s Work, we believe delivering high-quality safety training is only the beginning. The real challenge? Ensuring your employees complete it—and take it seriously.

Topics: Engagement, AgriBot

Introduction to Tire Balancers

Tire balancers are essential tools for achieving smoother rides, better handling, and prolonging tire life. Whether you're mounting new tires, realigning wheels, or minimizing vibrations, tire balancers are the backbone of precision in vehicle maintenance. They evenly distribute weight across the wheel and tire assembly, enhancing both safety and performance.

Topics: Tools

Introduction to Porta Powers

Porta powers are compact hydraulic tools built for precision and strength, making them essential for tasks like straightening frames, spreading metal, or aligning panels. Perfect for automotive shops, heavy equipment repairs, or on-site work, their portability and versatility let you tackle tough jobs efficiently.

Topics: Tools