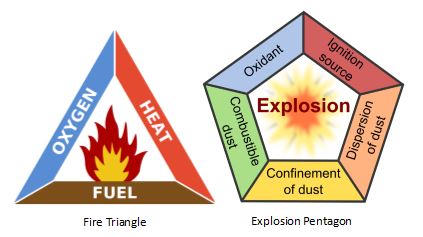

To understand grain dust explosions, it is helpful to understand the elements that make up the fire triangle and the explosion pentagon. Many people are familiar with the fire triangle of heat, fuel and oxygen. By removing one of the three elements of fire, you can prevent or put a fire out. OSHA says five elements must be present for a dust explosion to occur. They are heat, fuel, oxygen, dispersion of dust and confinement. Industry experts sometimes refer to this as the explosion pentagon. Like fire, if any of the 5 elements are removed, an explosion cannot occur.

Fugitive Grain Dust or Combustible Dust

When handling grain, dust particles will be created. Fugitive dust is dust that escapes into the atmosphere and is suspended in air. It collects on floors, ledges, beams and any exposed equipment. In grain handling, this fugitive dust is also combustible dust when conditions are right. According to OSHA Standard Requirements, fugitive dust must be removed when accumulations exceed 1/8”.

Two Separate Explosion Phases

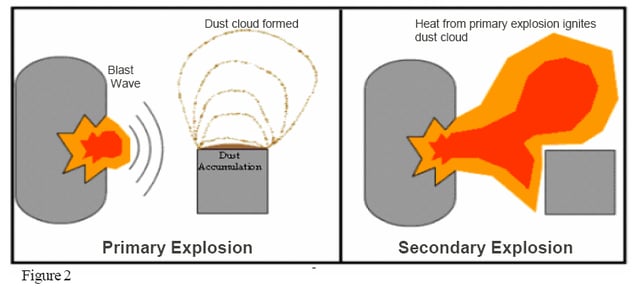

It’s important to understand what happens in a major dust explosion. There are really two explosions that happen very quickly, one right after another. The initial explosion usually occurs within the confinement (for example) of the bucket elevator or conveyor when dust encounters a heat source and ignites. The blast from the initial explosion dislodges and suspends the fugitive dust which has accumulated into the air where it ignites and causes the second explosion (see illustration below). This explosion is normally much larger and is a more catastrophic explosion. The 5 elements of the explosion pentagon must be present for the first blast and second blasts. The two most important factors in preventing an explosion are keeping the facilities clean to minimize the fuel source and keeping the equipment in good working order to minimize the chance for ignition.

Here are two YouTube videos that are helpful in understanding the force and power of a grain explosion. In both these videos no one was hurt. The first one is a grain elevator and the second is an on farm grain bin system.

Grain Elevator – Blast Caught on Camera

On Farm Grain Bin Collapse and Grain Dust Explosion

Advice From An Expert

When it comes to an ignition source Kingsly Ambrose, an assistant professor of agricultural and biological engineering at Purdue University says, “I always tell people to keep their eyes, nose and ears open - if you see something strange, hear an odd noise or smell something unusual, then that’s the time to shut down and check all the equipment." When it comes to minimizing the fuel source he also says, “It’s not about completing a one-day maintenance and thinking you’re done for the year. It’s a constant, ongoing process.”

Preventing Grain Dust Explosions

To reduce the risk of a grain dust explosion or fire, focus on controlling dust and reducing the sources of ignition. Preventative measures include continuous housekeeping, sanitation, and regularly scheduled maintenance. Implement a housekeeping or sanitation program to decrease grain dust in all work areas. Leg boots should be cleaned routinely to remove excess dust and kernels. Additional preventative steps include:

- Developing and implementing a routine lubrication plan for bearings on the basis of the manufacturer’s recommendations

- Developing and implementing a standard operating procedure (SOP) for housekeeping practices to minimize grain dust accumulation

- Using a food-grade mineral spray on grain that is being transferred

- Installing a bearing-temperature monitor in strategic locations throughout the grain handling system and implementing a program to periodically monitor bearing temperature

- Installing belt-rub sensors inside bucket-elevator leg casings

- Substituting steel cups with plastic cups in elevator legs

- Using antistatic belting material in legs and horizontal belt conveyors

- Establishing easy-to-open cleanout doors in the leg-boot side panel for easy removal of grain and dust

- Installing dust aspiration systems or a ventilation system at grain transfer points

- Training employees in safe work practices so that they can recognize and prevent hazards that could lead to a grain dust explosion

- Posting No Smoking signs and actively enforcing the rule

- Completing regularly scheduled inspections to locate any defective wiring or sparking and make repairs as needed

Information on the preceeding paragraph is sourced from: Farm and Ranch eXtension in Safety and Health (FReSH) Community of Practice

Training

To help prevent explosions and keep people safe, train your employees as a first line of defense. When they armed with information and training on combustible dust hazards, they can be instrumental in recognizing unsafe conditions, take preventative action or alert their supervisors or management. Training employees on safe work practices helps ensure everyone Get Home Safe.

Good Day's Work is a great resource for training employees.

In Summary

I genuinely like the two live videos attached as real examples of a grain dust explosion. Take time to view them. Though many people have not experienced a grain dust explosion, these videos can demonstrate the force and magnitude an explosion has. Educate your employees on how grain dust explosions occur and train them in measures to reduce the risk. Controlling dust and reducing sources of ignition are key to keeping people and your facilities safe.