When employees are not mandated to wear respiratory protection, do they know enough to protect themselves? It’s one thing to make decisions for yourself when you have a good knowledge base. It's another thing to be unaware. Have you ever been in a position where you thought to yourself, “I wish someone would’ve told me about this a long time ago?”

That’s where this blog comes into play concerning non-mandated respiratory protection. In particular, the voluntary use of a disposable particulate dusk mask, also referred to as filtering facepiece, mechanical filter or particulate respirator.

As a HR director, you want your employees to be armed with good information about respiratory protection, so they can make good decisions regarding their health. When you educate and train employees they can be fully responsible for their actions. When employees are unaware of health hazards and they lose their health, they’ll feel they’ve been done WRONG!

Let’s look at 6 key pieces of information that are vital for you as the HR director to educate and train on, so you are responsible for doing your employees RIGHT!

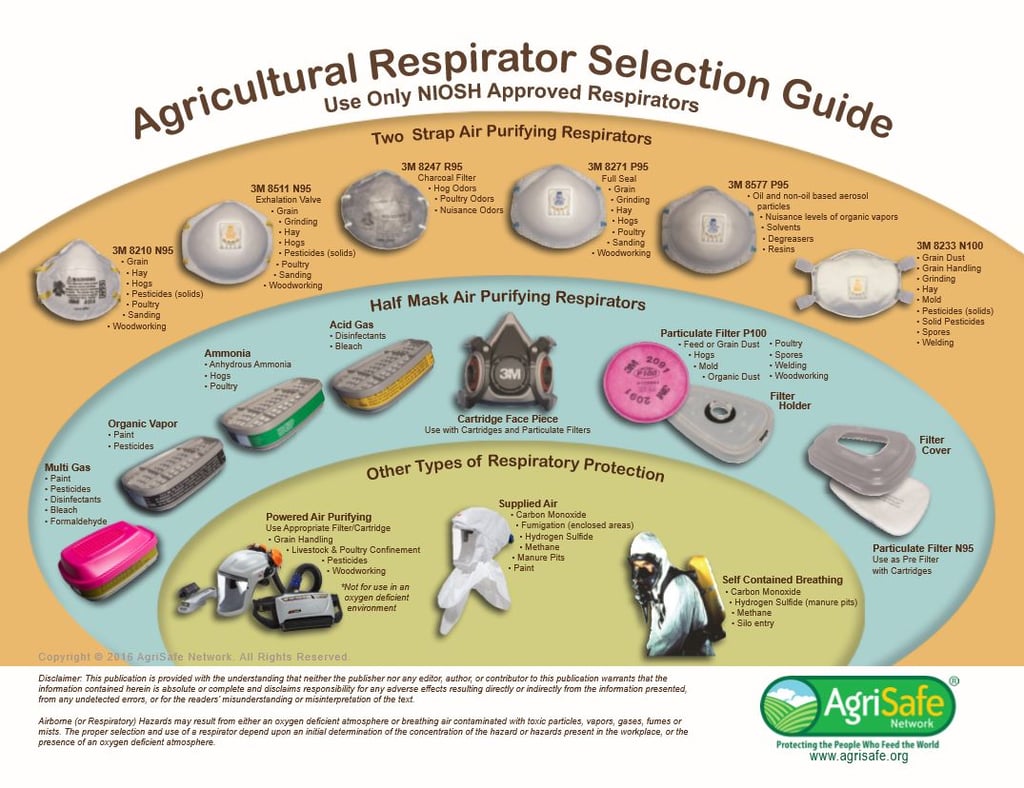

You can find the above selection guide on the AgriSafe Network website.

1. OSHA Requirements for Voluntary Use of a Dust Mask

OSHA places two requirements on employers when it comes to allowing employees to wear dust masks voluntarily:

- Employers must determine that the masks themselves do not pose a hazard to workers.

- Employers must provide the information found in Appendix D to 1910.134 of OSHA’s Respiratory Protection Standard to workers on a one-time basis.

Respirators are an effective method of protection against designated hazards when properly selected and worn. Conversely, they can also be a hazard to the worker if not used right.

2. Know Particulate Dust Factors

Consider these factors when determining health effects of particulates;

- Length of exposure (how long the person is breathing in the dust particles , e.g. 2 or 8 hours)

- Type and toxicity of contaminants

- Concentration level of contaminants (amount of particles in the breathing zone)

- Size of particles (affects how deep within the respiratory system the matter can go and how long the dust will remain in the air)

- Activity level and breathing rate (breathing through a respirator is harder than breathing in open air)

- Age and overall health (people with lung diseases such as asthma or emphysema, elderly people and others may have trouble breathing)

These factors come into play when considering wearing dust masks. The better employees can understand these topics, the better they can make informed decisions on the best respiratory protection for their short and long-term health.

3. Know Particulate Dust Types

Know the differences between respiratable dust and inhalable dust. Because you can't see dust suspended in air, doesn't mean it's not present.

Respirable Dust are particles < than 10 µm (microns) and are small enough to penetrate the nose and upper respiratory system and deep into the lungs or gas exchange region. Generally, beyond the body’s natural clearance mechanisms of cilia and mucous and are more likely to be retained.

Inhalable Dust is dust which enters the body, but is trapped in the nose, throat and upper respiratory tract.

4. Know NIOSH N95 Respirators

All air purifying respirators (APR) used in agriculture should be approved and certified by National Institute of Occupational Safety and Health (NIOSH). APRs come in a variety of ratings that relate to how they perform and what environment type it is designed to be used in. N95 respirators are common, the N stands for "not oil resistant" and the 95 means it removes 95% of all particles that are at least 0.3 microns in diameter. They are designed to fit over the nose and mouth of the wearer, and properly fitted can provide excellent protection. All N95 respirators will have two straps that go around your head.

N95 / R95 / P95 masks filter out 95% of dust particles (R=Resistant to oil P=Oil Proof)

N99 / R99 / P99 masks filter out 99% of dust particles

N100 / R100 / P100 masks filter out 99.7% of dust particles

It is important to understand dust or particulate respirators only protect against particles. They are the simplest, least expensive and least protective type of respirators available. However, when used correctly, is ideal for providing respiratory protection in many agricultural environments. Particulate respirators are "air-purifying respirators" because they clean particles out of the air as you breathe. Even particles you can't see. In agricultural situations, it's important to recognize when a particulate respirators are needed and that they can only protect the worker when they wear them.

5. Training for Respirators Makes A Difference

There are many different kinds of dust respirators for ag operations. Training is required for anyone who wears a respirator to know how to protect their health and select the proper type of respirator for the job.

Proper fit testing is also important. Dust masks need to fit your face properly and make a tight seal. 3M has a fit guide called Helping You Wear it Right. This easy to understand guide is available in English and Spanish. OSHA provides a video on Respiratory Fit Testing, it too is available in English and Spanish.

Training is critical for wearing a dust mask. When worn incorrectly, a mask can be ineffective even for a well intended employee. It is essential that there is a good seal formed between the dust mask and the skin with nothing in between. Facial hair can prevent a mask from making a good seal and if not clean-shaven effectiveness will be compromised. It is up to the employee to recognize facial hair can compromise their health when wearing a mask.

6. Respiratory Protection Is Effective When:

A. the correct respirator is used

B. it's available when you need it

C. you know when and how to put it on and take it off

D. you have stored it and kept it in working order in accordance with the manufacturer's instructions

Respiratory protection can be complex with many variables in ag. However, the effectiveness in general boils down to these four key points. As a HR director, you can provide education and training to help assure the respiratory protection for your employees.

Employers have the primary responsibility to provide respiratory information to make employees aware of risks and how to mitigate them. You don't want a situation where employees are simply unaware of the risks and not provided resources to protect themselves. In turn, employees are responsible for following the safe work practices. Additionally, when protection is not mandatory, employees should be armed with information and awareness, so they can make informed decisions that will ultimately protect their health.

Summary

Workers in agriculture are exposed to a variety of respiratory hazards. It is essential that these workers understand how to protect their respiratory system in high and in low concentrations of harmful dusts. Healthy breathing in dusty environments will help keep your employees healthier and more productive. As an employer, it's your responsibility to provide these tools to help your employees Get Home Safe.