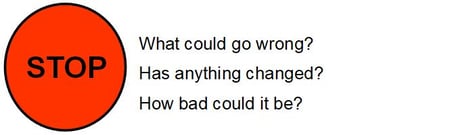

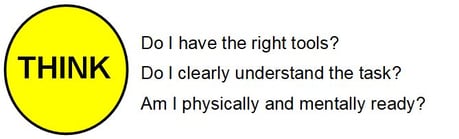

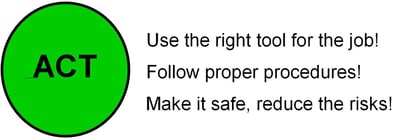

Consider this safety tool when addressing a task or chore.

Here's a simple safety tool to consider before addressing a task or a chore to be done. This could be a good topic to discuss at your next meeting. Each statement can have a specific reference to tasks you do in your operation. My two favorites are; "has anything changed and do I have the right tools?" Let's encourage everyone to just stop and think before they begin.

Grain Bin Safety

Over the next three months, many growers will continue emptying their bins and hauling grain. Let's not get relaxed when it comes to grain bin safety. Use the stop, think and act tool before entering grain bins. Here are a few things to review when it comes to grain bin safety.

Check Grain Often

Continue to check on bins regularly for storage temps, insect infestation, and mold. If you need to enter a bin, always take the necessary precautions. Never work alone. Check the oxygen level with a gas monitor. Is there potential for combustible gas, vapors, or toxic agents? Use the permit-required confined space permit. Utilize a safety harness, lifeline, grab-rope, have a second person (attendant) outside the bin to monitor the entrant, and have appropriate respiratory protection.

Correcting a Storage Problem

Don’t count on long-term storage with poor quality grain. Keep your best grain for long-term storage. When you find a storage problem, it is important to correct it as soon as possible. If grain shows signs of heating up and or molding, the first option is to aerate to cool the grain back down. If that cannot correct the problem, removing the problem grain is the next option. Addressing a grain problem when it’s small is better than having spoilage throughout the bin. It’s important to note that you cannot improve grain quality in the bin…however you can preserve it depending on conditions and time of year.

Checking Bins

By checking grain quality regularly, grain storage issues can be headed off, thus reducing the need to enter a bin. However, checking bins with regularity also poses some safety risks. Always keep both hands free while you climb (ladder or stairs). Use a tool belt, carry a backpack, or use a bucket on a rope to keep your hands free to climb safely. Anytime a worker climbs something, ladders, combines, tractors, sprayers or anything structural such as grain bins, they should practice 3 points of contact.

Go slow..... Keep it slow and steady and don’t rush. Always face the ladder. Always keep the body inside the rails and avoid overreaching. Ensure the climbers are in the right state of mind and focused only on the task at hand. A loss of focus could result in a fall.

Final Words

- Discuss with employees "Stop - Think - Act" words in order to keep safety top of mind. Especially when working around grain systems.

- Don't let your guard down as we finish up emptying grain bins and hauling grain. It may seem routine, you've not had any problems thus far, however, the grain doesn't care about your past history.

- Do you have the right masks or respirators available?

- Emphasize the need for everyone to protect the respiratory system when working around the grain. No, you don't feel any pain when you don't wear a mask and you may tell yourself you'll be fine. However, your body will thank you years later when you're older by protecting it now.

- Are hearing protection devices available for wearing around noisy equipment? Are people wearing them? Like the respiratory system, everyone needs to protect their hearing today so they don't have to continually ask people to "repeat that" when they're older.

- Here is a blog on Grain Entry Checklist which goes through the Permit-Required Confined Space. A grain bin is a permit-required confined space. A great tool to teach employees to use the permit before entering a grain bin.

I wish you nothing but safety for you, your family, and your operation as we finish up spring activities.

Thank You for looking out for the safety of YOUR TEAM!

Marty Huseman and the Good Day's Work Team