When you and your harvest crew gear up for fall harvest, we hope you first follow our tips on how to prep your farm for this season. After you have, take a look at these common combine hazards, so you're as safe as possible on the job.

Good Day's Work

Recent Posts

Topics: tractors, hazard communication, combines

Harvest is a time when many different types of powered equipment will be used and will need to be serviced and repaired. If you’re the person responsible for servicing or repairing a piece of equipment, you want that “peace of mind” knowing that nobody could accidently startup the equipment while you’re working on it. There is only one way to assure your safety and the safety of employees…. that is with a Lockout-Tagout (LOTO) program.

Topics: lockout-tagout (LOTO)

Running a Farm Safety Program: Getting Employee & Management Buy-In.

Your farm-safety program doesn’t have to be complicated, but, for it to work, everyone in the operation needs to buy into it. These seven steps will help you convince managers and employees to take ownership of the safety program and drive the safety agenda.

Topics: safety culture, safety training program, agriculture

Hazard Assessment: How to find the high risk safety issues on your farm

Compared to other industries, farm work is the most dangerous of all. Every year, more than 480 people in the US are killed performing ag-related jobs. Hundreds more are seriously injured. According to OSHA, it is the employer’s responsibility to evaluate the workplace and ensure a risk-free environment.

Topics: hazard communication, hazard analysis

Farm Safety Tips: Making the Case for Hearing Protection...

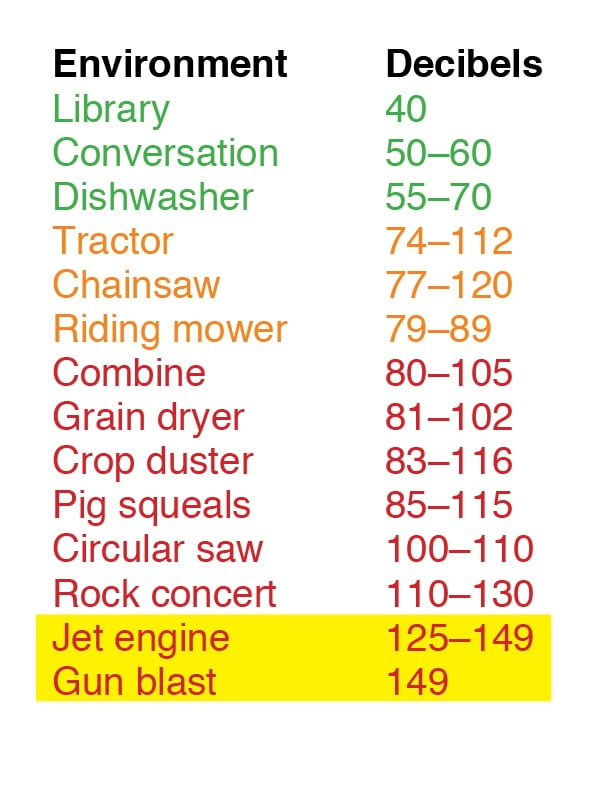

On the farm, we use our hearing to do our jobs better. The problem is, when it comes to hearing safety, most threats are long term. We don’t sense any immediate harm. This week's farm safety tips address why it’s important to train your employees on hearing protection.

Topics: farm, personal protective equipment (PPE)

Farm Safety Tips: Respiratory Protection and Keeping You Safe

Ah, the great outdoors—crisp, clean air and the refreshing smell of morning dew! Yes, this is just one of the reasons many of us really love farming. On the other hand, does farming generate hazards for our respiratory systems? Not only is the answer a resounding “yes,” but some of the most treacherous respiratory dangers are actually unique to farming.

Topics: air/respiratory, agriculture, chemicals

Calculating an OSHA Penalty

Topics: OSHA law & compliance, agriculture

Earlier this week, we discussed the first fundamental reason for having someone on your staff—even if it’s you—dedicated to safety. Having a single point-person fulfill this role is critical to maintaining the clear, consistent communication that optimizes safety among your employees.

Topics: safety director, OSHA law & compliance

If you’re running an agribusiness, you probably rely on a few key people for their expert opinion or advice, like your vet or crop specialist. Now that you’ve decided to ramp up the operation’s ag safety program, you might be looking to expand that list of trusted advisers to include a safety director or safety consultant.

Topics: safety director, OSHA law & compliance

Are Safety-Training Videos Enough to Meet OSHA Compliance?

For agribusiness owners considering options for employee safety training, the question often arises--Will videos alone satisfy OSHA requirements, or do I have to hire a safety expert to come on site and conduct some kind of formal training?

Topics: agriculture