The main goal of a safety and health program is to prevent workplace injuries, illnesses and fatalities, as well as the suffering and financial hardships these events can cause workers, their families and your operation. I believe we can all agree with that as the ideal.

From the feedback we received from recent surveys, HR directors and safety managers are looking for more information on job hazard analysis and hazard identification. I’m going to embark on a 4-part series addressing hazards to help further your understanding. By reading this blog, you'll:

- have better insights into different aspects of hazard analysis

- understand the role that hazard analysis play in a solid safety and health program.

Why Care About Hazard Analysis?

You’ll want your program to be ahead of the game by “finding and fixing” workplace hazards before they can cause an injury or illness. Finding and fixing is by far the better approach than reacting. You’ll find using your resources to prevent accidents, costs much less than the direct and indirect costs associated with an incident. Hazard analysis is a proactive and ongoing process that builds each year.

Hazard identification is only part of a sound safety and health program. Benefits include:

- Prevent workplace injuries and illnesses (#1 goal)

- Improve compliance with laws and regulations (such as OSHA)

- Reduce direct and indirect costs (this is big)

- Engaged workers (everyone’s participation and responsibility, not the HR or safety person)

- Increase productivity and enhance overall business operations

- Improvements in product, process and quality

- Better workplace morale

- Improved employee retention and recruiting

- Favorable image and reputation (customers, suppliers and community)

Workplace injuries and illnesses have a major impact on an employer’s bottom line. Direct costs include workers’ compensation payments, medical expenses, legal services and possible OSHA fines. Implementing a safety and health program where hazards are eliminated or minimized avoid indirect costs that can be up to 3 times that of direct costs. Can you see how these indirect costs can add up?

- Any wages paid to injured workers for absences not covered by workmans' compensation

- The wage costs related to time lost through work stoppage associated with the worker injury

- The overtime costs necessitated by the injury

- Administrative time spent by supervisors, safety personnel, and clerical workers after injury

- Training costs for a replacement worker

- Lost productivity related to work rescheduling, new employee learning curves, accommodation of injured employee(s)

- Clean-up, repair and replacement costs of damaged material, machinery and property

- Time lost due to work stoppages, investigations and training

- Implementation of corrective measures

- Lower morale and absenteeism

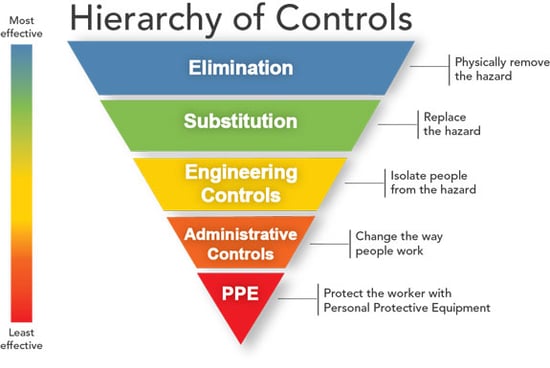

Use the Hierarchy of Controls To Prioritze Hazards

Hierarchy of hazard control is a system used to minimize or eliminate exposure to hazards. Many of you are familiar with this. I find the hierarchy of control foundational to job hazard analysis. Refer to this chart as an easy way to approach hazards that you identify and seek to eliminate or mitigate. I won’t go deep into this, you can learn more going to NIOSH Hierarchy of Controls.

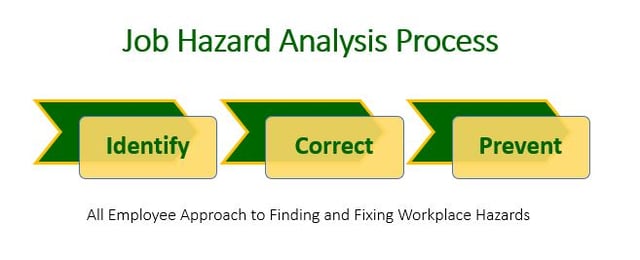

The Job Hazard Analysis Process

When you implement a job hazard analysis process, it will boil down to three things; identify, correct and prevent. These three pillars of the hazard identification process will be the subject of my next 3 blog posts where we’ll take a more in-depth look. Each are key to a successful program when executed correctly.

Identify - Hazard ID & Assessment

- Collect existing info

- Inspect workplace

- Identify Hazards (safety or health)

- Conduct Incident Investigations

- Prioritize Hazards (worst-first)

Correct - Hazard Prevention and Control

- Identify Control Option(s) for each hazard (from prioritized list above)

- Develop Hazard Correction/Control Plan (how to document the plan)

- Implement the Plan (make the correction)

- Follow-up/Check on Changes

Prevent - Education & Training

- Knowledge and skills to work safely

- Awareness and understanding of workplace hazards -how to identify, report and control them

- Specialized training when work involves unique hazards

- Program evaluation and improvement

Before we ever get started, give some thought to process documentation. You’ll want a simple way to document the steps and processes used in hazard identification, correction and prevention. Keep it simple at first and realize you can improve the process each year. If the processes are too involved, it will seem like too much work and will be avoided rather than used.

Think about where this information will be stored and how it will be organized. Think about who has access to the files if it’s electronic or where a hardcopy can be accessed. Keep in mind to be effective, any safety and health program needs the meaningful participation of employees. They know the most about potential hazards and are key to finding and fixing them before an incident ever occurs. Envolving employees is also key to maintaining a strong safety culture.

Good documentation will give you a benchmark for taking action and moving your program forward. You’ll see in the next few blog posts that you don’t have to everything identified and mitigated from day one. What you will see is a process to identify hazards and prioritize worst to first. You take on what you can and establish an on-going improvement process that will take your program to the next level. Employees benefit as do employers.

Summary

Job hazard analysis is part of a successful safety and health program. By fostering a proactive approach to “finding and fixing” hazards, your business can minimize hazards that may cause an injury or illness. Losing workers to injury or illness, even for a short time, can cause significant business disruption and cost to your business as well as to workers and their families.

A job hazard analysis program sets your business up for sustainability well into the future. Engaging employees through each step gets them personally involved and vested to assure their safety as well. It is key to maintaining and growing a strong safety culture. Workers have much to gain from a successful program and the most to lose if the program fails.

Stay tuned for upcoming blogs where we will address these three areas identify, correct and prevent in order to help you get started or make adjustments to your safety and health program.