Editor's Note: Updated Dec 18, 2017. OSHA pushed back the deadline from Dec 15 to Dec 31, and has said they will not take enforcement action on those who meet the Dec 31 deadline (see source here). Starting Jan 1, 2018, OSHA will no longer accept 2016 data.

6 Steps to Nail Compliance for OSHA's New Electronic Reporting Rule

Topics: OSHA law & compliance

There’s something intimidating to the average person viewing Safety Data Sheets (SDS) with all the scientific words and a mountain of detail. It no doubt looks like “work” to try to decipher a typical sheet and a bit overwhelming.

Would employees feel the same way if they became more familiar with SDS and knew how to break it down to where it wasn’t information overload? Let’s be honest, to most employees, that SDS binder or that computer for SDS information lookup is someone else’s job not theirs. All workers need to know how to access hazardous chemical information. Here are three steps to simplifying SDS sheets so employees can refer to them as a resource of information.

Topics: chemicals

Slip, trip and fall (STF) injuries are common in agribusiness, especially in the winter time. Prepare now to minimize slip, trip and fall hazards around your facilities and before the ice and snow arrive. Grab a clipboard and pad and make a list of the top 3-5 most obvious areas that have given employees problems in the past. Then get feedback from employees where they feel STF hazards are around the operation. Next do a walk around to find areas that are potential walking and working surface hazards. This should include areas where there is clutter, reduced or blocked exits, uneven surfaces and areas where water, ice or snow can accumulate.

Topics: seasonal, slips/trips/falls

Have you ever installed carbon monoxide detectors in your farm buildings? If you haven’t, this may change your mind. A carbon monoxide detector or CO monitor is a devise that detects the presence of carbon monoxide (CO) gas to prevent carbon monoxide poisoning. CO is a colorless, tasteless and odorless compound produced by incomplete combustion of carbon-containing materials. It is sometimes referred to as the “silent killer” because it is virtually undetectable without using a detection devise.

Topics: carbon monoxide

Are you and your employees prepared for the fall handling of anhydrous ammonia (NH3)?

Before anyone begins to work around or with anhydrous ammonia it may be best to review your employee roster and see who has been trained and who has not. It is commonly reported that injuries of all types are more prevalent with first year employees. Don’t let new employees slip through the cracks and assume they’ve had adequate training, be absolutely sure. Employees not directly involved with anhydrous should also be trained as they need to know what to do and what not to do should an incident arise. The hazardous nature of working with anhydrous ammonia leaves very little room for error, especially for those who don’t understand the hazards.

Topics: anhydrous ammonia, first aid, personal protective equipment (PPE)

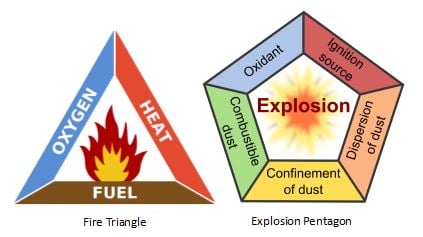

To understand grain dust explosions, it is helpful to understand the elements that make up the fire triangle and the explosion pentagon. Many people are familiar with the fire triangle of heat, fuel and oxygen. By removing one of the three elements of fire, you can prevent or put a fire out. OSHA says five elements must be present for a dust explosion to occur. They are heat, fuel, oxygen, dispersion of dust and confinement. Industry experts sometimes refer to this as the explosion pentagon. Like fire, if any of the 5 elements are removed, an explosion cannot occur.

Topics: grain bins, dust explosions

Why Conduct Incident Investigations - Use Root Cause Analysis

“Those that don’t learn from the past are doomed to repeat it.” This quote will be around forever. Which leads me into this blog post on “why conduct incident investigations?” Simply put, so the same incidents are not repeated. Injuries are reported because OSHA requires it. However, many incidents stop at the report stage.

Topics: incident investigations, checklist

Falls in agriculture account for many serious injuries. One area I’d like to cover is falls from grain bins, silos and grain dryers. It’s difficult to quantify how many falls from bins there are because so many falls go unreported. Although less frequent than other falls in agriculture, falls from grain bins are more often severe to fatal. In this blog, we raise several key issues that managers may consider for the sake of safety and fall protection.

Topics: climbing & falling from heights

Dupont Bradley Curve - Should I Learn More About Safety Culture?

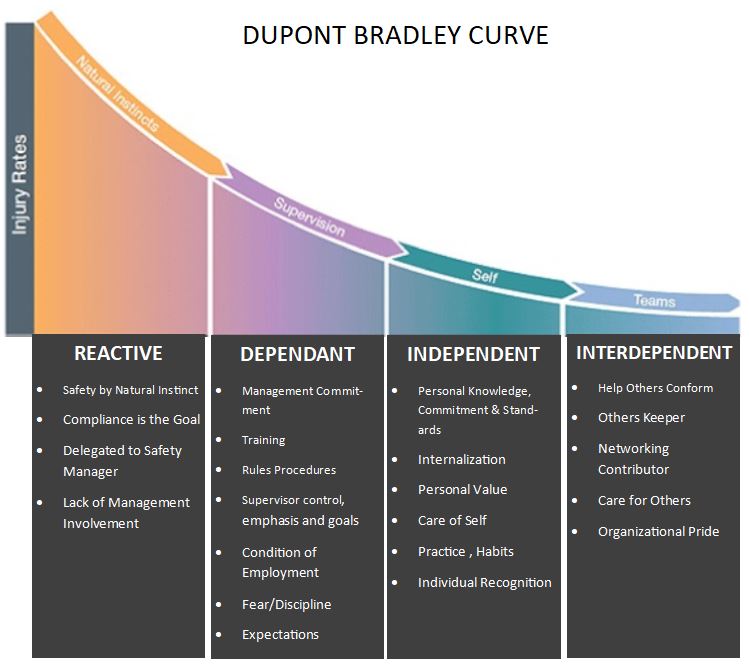

Why would a big corporation’s safety culture model have any relevance to safety in Agriculture? If you are not familiar with the DuPont Bradley Curve, I strongly suggest learning more about it as it can shape how you think about safety first and its effect on productivity, quality of work, the work environment and profitability. The Bradley Curve shows an evolution of an organization's safety culture. This model allows you to place your organizations' culture along the curve and give insights to the vision of zero injuries.

Topics: safety culture, OSHA law & compliance, productivity / goals / motivation

OSHA Inspection - What Will They Be Looking For? (PART 3 of 3)

This is the final part of a 3 part series on OSHA inspections. If you have not read the previous parts, go back and do that:

Click here for Part 1 - Why would OSHA pay me a visit? and click here for Part 2 - What to do when they show up?.

Can you pass these 5 commonly cited areas with your operation?

On my last post; OSHA Inspection – What to do when they show up (part 2) we covered things to know prior to an OSHA inspection. In this blog I want to address what OSHA might be looking for when they arrive for an inspection.

Topics: confined spaces, lockout-tagout (LOTO), machine guarding (PTOs/augers), OSHA inspections & violations, hazard communication, personal protective equipment (PPE), hazard analysis