Introduction to Portable Band Saws

Portable band saws offer precision and portability, making them essential for various cutting tasks. From metal pipes to wood and irregular materials, they deliver efficiency and accuracy. Their compact design and mobility are ideal for construction sites, maintenance work, or DIY projects.

Portable band saws offer precision and portability, making them essential for various cutting tasks. From metal pipes to wood and irregular materials, they deliver efficiency and accuracy. Their compact design and mobility are ideal for construction sites, maintenance work, or DIY projects.

What sets portable band saws apart is their adaptability. Lightweight models excel at intricate tasks like curved cuts or tight spaces, while heavy-duty versions handle demanding materials with extra power and capacity. With the right blade, they can cut through tough materials like steel and aluminum or shape softer materials like wood and plastic, making them invaluable across industries like construction, plumbing, metalworking, and woodworking. Hobbyists also appreciate them for creative projects like furniture crafting or custom fabrication.

Modern portable band saws often include ergonomic designs, adjustable speed settings, LED lights, and features like tool-free blade changes and dust collection systems, enhancing convenience and functionality. Whether you're a professional or a beginner, a portable band saw provides a versatile, reliable cutting solution, combining power and precision for any toolkit or workshop.

Recognizing the Risks

- Blade Kickback

When the blade jams or binds, the saw can kick back with force, putting the operator at risk of serious injury. Stay sharp and stay safe!

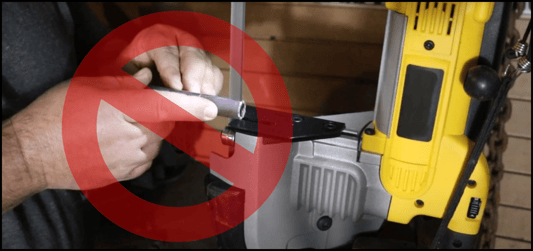

- Improper Handling

Losing a secure, two-handed grip or letting your fingers wander too close to the blade? That’s a fast track to cuts, slips, and loss of control. Keep your hands steady and your focus sharper than the blade.

- Environmental Dangers

A messy workspace isn’t just annoying—it’s dangerous. Clutter, unstable surfaces, or shifting materials can trip you up or throw your cuts off alignment. Tidy up before you power up!

- Electrical Hazards

Frayed cords, damaged wires, or the wrong power source can spark trouble—literally. Check your equipment and power supply to avoid shocks, sparks, or worse.

Mastering Portable Band Saw Safety

1. Gear Up with the Right PPE

Safety first! The right Personal Protective Equipment (PPE) sets you up for a smooth and secure cutting experience.

- Safety Glasses or Goggles: Protect your eyes from flying debris—and for metalwork, throw in a face shield for extra defense.

- Hearing Protection: Prolonged noise can take a toll. Keep your ears happy with earplugs or earmuffs.

- Gloves: Look for gloves that balance a firm grip with tough protection against cuts and scrapes.

- Respirators or Dust Masks: If you’re working in dusty or poorly ventilated conditions, protect your lungs from harmful particles.

- Slip-Resistant Shoes: A steady stance prevents slips, trips, and falls, so you can focus on the task at hand.

2. Prep Your Tool and Workspace

A tidy, well-prepared workspace is the foundation for safe and successful cutting.

- Give your saw a quick check before starting—inspect for dull blades, damaged cords, or anything that seems off.

- Tighten the blade and check the tension. Replace any blade that’s dull or chipped—it’s not worth risking a mishap.

- Declutter your workspace! Move loose cords and trip hazards out of the way, and make sure your area is well-lit for a crystal-clear view.

- Keep your materials secure with clamps or vises. No one wants a shifting board mid-cut!

3. Cut with Confidence

When it’s time to get to work, focus is everything.

- Keep both hands firmly on the saw for maximum control.

- Let the blade rev up to full speed before starting your cut—this avoids wobbles or accidents.

- Apply steady, even pressure. Don’t force the saw; let the blade do the work.

- Watch out for sharp or hot edges on completed cuts, especially when working with metal.

4. Love Your Tool, and It’ll Love You Back

A well-maintained band saw is a band saw that lasts.

- Regularly check blades, cords, and components for wear and tear. Replace anything that looks past its prime.

- After each use, give your saw a quick clean to prevent debris buildup.

- Store your tool in a dry, secure spot. For cordless saws, keep the battery separate to protect it from extreme heat or cold.

Lessons from Real-Life Incidents

Case Study 1: The Cost of Skipping Blade Inspections

Picture this: a worker begins an important project, eager to meet deadlines and get the job done. In their haste, they skip one crucial step—checking the condition of their equipment. Without inspecting the blade, they dive into the task at hand. Everything seems fine at first, but then disaster strikes. Mid-cut, the old, worn-out blade snaps under pressure. The saw kicks back violently, causing a serious injury to the worker's arm. Not only is the worker hurt and in pain, but the entire project comes to an abrupt halt. The team loses valuable time addressing the injury, filing incident reports, and waiting for replacement parts to arrive. All of this could have been avoided with a simple preventative measure.

Picture this: a worker begins an important project, eager to meet deadlines and get the job done. In their haste, they skip one crucial step—checking the condition of their equipment. Without inspecting the blade, they dive into the task at hand. Everything seems fine at first, but then disaster strikes. Mid-cut, the old, worn-out blade snaps under pressure. The saw kicks back violently, causing a serious injury to the worker's arm. Not only is the worker hurt and in pain, but the entire project comes to an abrupt halt. The team loses valuable time addressing the injury, filing incident reports, and waiting for replacement parts to arrive. All of this could have been avoided with a simple preventative measure.

This scenario highlights an important lesson: taking a few minutes to inspect tools and replace worn-out components can save you from injuries, downtime, and unnecessary stress. Skipping safety checks might seem like a small shortcut, but it can lead to big consequences. Prioritizing regular equipment maintenance not only protects workers but also keeps projects running smoothly and on schedule.

Case Study 2: When the Workpiece Fights Back

Imagine starting a job with a steel pipe that wasn’t properly clamped. That’s what one operator did, and the result was far from ideal. The material shifted mid-cut, ruining precision and leaving a jagged, uneven finish. Worse, the blade snapped under the unexpected movement, adding unnecessary costs and downtime. Beyond the financial impact, unsecured materials created a serious safety hazard, risking accidents, injuries, or equipment damage.

Imagine starting a job with a steel pipe that wasn’t properly clamped. That’s what one operator did, and the result was far from ideal. The material shifted mid-cut, ruining precision and leaving a jagged, uneven finish. Worse, the blade snapped under the unexpected movement, adding unnecessary costs and downtime. Beyond the financial impact, unsecured materials created a serious safety hazard, risking accidents, injuries, or equipment damage.

The lesson is simple: always secure your materials. A steady foundation means accurate cuts, protects your tools, saves time, and keeps you safe. Taking a moment to double-check clamps can mean the difference between success and costly mistakes.

Best Practices for Portable Band Saw Safety

- Training is Key: Make sure operators are fully equipped with the knowledge they need to handle tools safely and effectively.

- No Shortcuts Allowed: Rushing leads to mistakes. Slow down, follow every step, and get it done right.

- Inspect, Inspect, Inspect: Always check tools, materials, and your workspace before you dive into the job. Safety first!

- Speak Up, Stay Safe: Encourage your team to report hazards and share safety tips. A strong safety culture benefits everyone.

Call to Action

Portable band saws are a game-changer—combining precision, power, and portability in one tool. But let’s not forget: safety always comes first. Have you used a portable band saw? Got a pro tip or a safety lesson that stuck with you? We’d love to hear your stories!

Portable band saws are a game-changer—combining precision, power, and portability in one tool. But let’s not forget: safety always comes first. Have you used a portable band saw? Got a pro tip or a safety lesson that stuck with you? We’d love to hear your stories!

Drop your insights in the comments and let’s build a community that works smarter, safer, and with confidence. Stay sharp, stay safe, and keep creating amazing things!