Introduction to Trailer Light and Air Testers

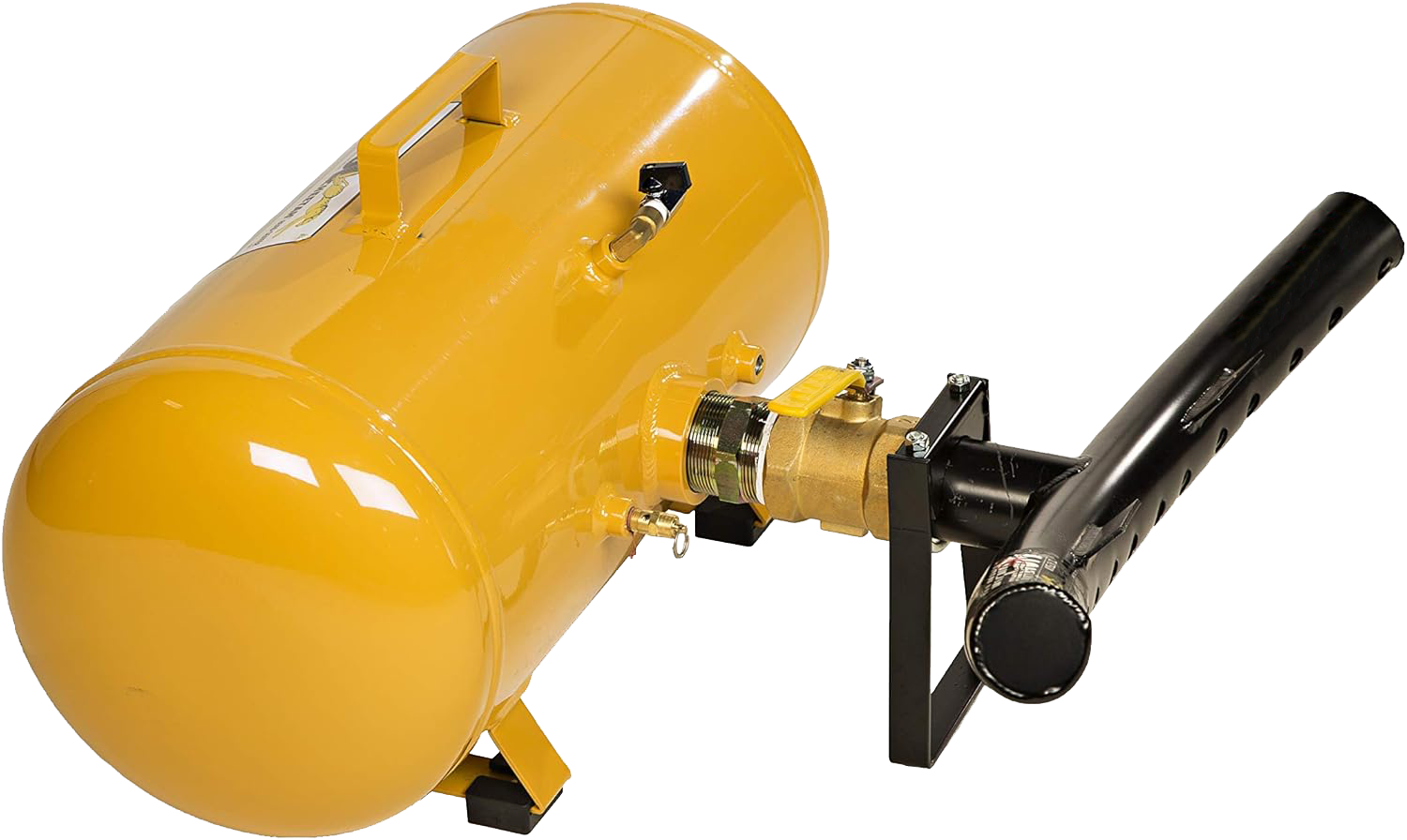

Trailer light and air testers are a must-have for anyone working with trailers, from seasoned drivers to fleet managers. These powerful tools keep your trailer’s electrical and pneumatic systems in top condition. Need to check brake lights, turn signals, or air pressure in the brake system? They’ve got you covered, making sure you’re safe and road-ready every time.