Good Day's Work

Good Day’s Work is a dynamic, web-enabled, OSHA safety-training and compliance-reporting software platform unlike any other you will find. It makes online training and program management remarkably easy for farm employees and supervisors alike. From the field to the shop, Good Day’s Work offers valuable online employee safety-training classes for virtually any task on any jobsite related to your agribusiness. All of the training’s subject matter is geared specifically for farm and other agribusiness operations, and the reporting platform goes beyond any other safety-training resource to make compliance as straightforward as possible for you—even in the event of a surprise OSHA inspection!

The EPA has revised the agricultural Worker Protection Standard and expanded the regulation to provide new worker protections similar to other industries.

Among other new protections, it now includes annual mandatory training to inform farmworkers on the protections afforded to them through the standard. Formerly, this training was required only once every 5 years.

Read More

Topics:

worker protection standard (wps)

It’s no secret that agriculture is one of the most dangerous industries in the world and that emergencies can happen any time. Unfortunately, emergency responders may not always be familiar with ag operations, meaning that rescues and treatment of injured employees may take much longer than normal. Precious minutes could easily be lost while responders determine the best way to get a trapped or injured employee to safety and treatment. Having an emergency action plan (EAP) in place for your operation can literally mean the difference between life and death in an emergency situation.

Read More

Topics:

emergency action plan

Agriculture is a dangerous industry. Fortunately, there are lots of ways to make it safer. Below are a few examples of good practices that will make your operation safer.

Read More

Topics:

safety culture,

agriculture

Slips, trips, and falls in the workplace are no laughing matter. In fact, they account for more than 225,000 injuries a year. And 70% of these incidents occur on level surfaces with falls from less than four feet above ground!

Read More

Topics:

farm,

slips/trips/falls

One moment you are having a casual chat with a co-worker over lunch. Suddenly, she grasps her throat and begins to turn blue. What do you do?

Read More

Topics:

first aid,

safety training program,

agriculture,

farm

Compared to other industries, farm work is the most dangerous of all. Every year, more than 480 people in the US are killed performing ag-related jobs. Hundreds more are seriously injured. According to OSHA, it is the employer’s responsibility to evaluate the workplace and ensure a risk-free environment.

Read More

Topics:

hazard communication,

hazard analysis

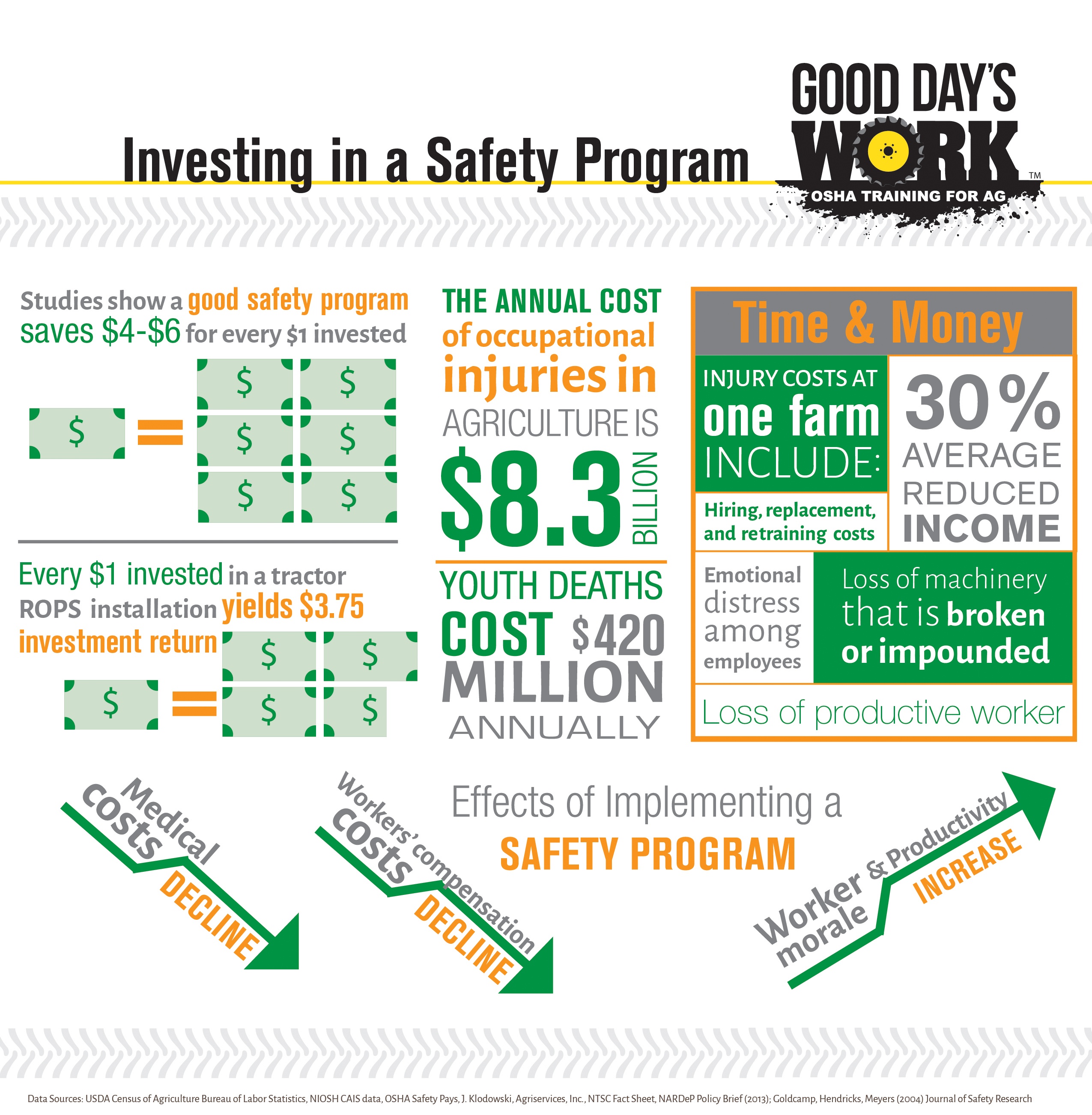

Investing in proper safety training is an important component of your operation’s preparations for a new year. As you can see below, just the financial costs of injuries – and deaths – from ag-related activities can cost your business thousands of dollars a year. And this is even before OSHA gets involved!

Read More

Topics:

safety training program

As an ag operation owner, you no doubt have an insurance plan in place in case something goes wrong. It's part of the price of doing business in the event of an accident or disaster. Sometimes, that insurance plan can mean the difference between staying afloat after a particularly difficult year and going under completely.

Read More

Topics:

safety training program

For many ag operations, winter is the “off-season,” making it an excellent time to ensure your employees have completed their annual safety training. It’s also a good time to conduct a hazard assessment of your operation. Here are four things you can do now to help ensure that your next year is as safe as possible.

Read More

Topics:

safety training program,

hazard communication,

hazard analysis

‘Tis the season for family, fun, and festivities. You’ve worked hard all year, and now it’s time to slow down and enjoy a little well-earned celebration. You’ve earned it. Just remember, for the sake of both you and your loved ones, to practice a little personal safety this holiday season.

Read More

Topics:

seasonal