National Farm and Safety Health Week is September 17 to 23, 2017. This year's theme is "Putting Farm Safety Into Practice." According to National Education Center for Agricultural Safety (NECAS) this theme hits home and reminds us that it is everyone's responsibility for safety both on the farm and the rural roadways of America.

Topics: agriculture, events & activities, farm

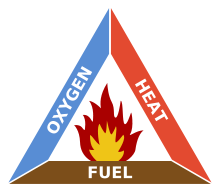

When getting your combine ready for harvest, have you thought about combine fire prevention? A combine fire extinguisher can put out a small fire before it grows out of control. Let’s review some basics of fire, review the type of fire extinguisher needed and view some combine recommendations:

Now is a great time to assess manure pit dangers and bone up on identifying hazardous gases as fall approaches. Many deaths happen late summer and fall when crops come off and producers are emptying pits. Everyone who works in or around manure storage (tanks, pits & lagoons) should understand manure gas hazards. A good resource for information is the Great Plains Center for Agriculture Health fact sheets at www.gpcah.org.

Topics: hazard communication, manure pit

During harvest, you have a huge amount of work to do within a very short window of time. Put yourself in the best position possible for a safe harvest season by being prepared. Here are some safety tips to think about before harvest and field operations.

When you and your harvest crew gear up for fall harvest, we hope you first follow our tips on how to prep your farm for this season. After you have, take a look at these common combine hazards, so you're as safe as possible on the job.

Topics: tractors, hazard communication, combines

Regardless of the crops you grow, harvest season is one of the most hazardous times of the year. There are a wide range of activities, extensive equipment operation, long hours, dust and chaff, multiple fire hazards, and time pressure that all increase the risk of injury.

Topics: harvest, safety training program

Harvest is a time when many different types of powered equipment will be used and will need to be serviced and repaired. If you’re the person responsible for servicing or repairing a piece of equipment, you want that “peace of mind” knowing that nobody could accidently startup the equipment while you’re working on it. There is only one way to assure your safety and the safety of employees…. that is with a Lockout-Tagout (LOTO) program.

Topics: lockout-tagout (LOTO)

Blended Learning refers to the use of a variety of training tools to maximize retention of the material. It may include a broad range of techniques including pre-knowledge assessments, performance goals, e-learning, live training, individual training, post-knowledge assessments and virtual or live coaching.

Topics: safety culture, safety training program

Running a Farm Safety Program: Getting Employee & Management Buy-In.

Your farm-safety program doesn’t have to be complicated, but, for it to work, everyone in the operation needs to buy into it. These seven steps will help you convince managers and employees to take ownership of the safety program and drive the safety agenda.

Topics: safety culture, safety training program, agriculture

Hazard Assessment: How to find the high risk safety issues on your farm

Compared to other industries, farm work is the most dangerous of all. Every year, more than 480 people in the US are killed performing ag-related jobs. Hundreds more are seriously injured. According to OSHA, it is the employer’s responsibility to evaluate the workplace and ensure a risk-free environment.

Topics: hazard communication, hazard analysis